In the field of industrial connections, the quality of stainless steel cable glands directly affects the safety of the entire system. Faced with a wide variety of products on the market, knowing how to quickly and accurately assess product quality has become an essential skill for procurement personnel and engineering technicians. Today, we will share 5 key indicators to help you make the right choice.

304 Stainless Steel vs. Inferior Materials

High-quality stainless steel cable glands use 304 or 316 stainless steel. The surface should exhibit a uniform metallic sheen, free of rust or burrs. When touched, the surface should feel smooth and even, without roughness. Inferior products often use 201 stainless steel or galvanized steel, appearing dull, prone to rust, and significantly shortening their service life.

Sealing Ring Material

Sealing rings should be made of nitrile rubber (NBR) or silicone rubber, offering good elasticity and quick recovery after compression. Inferior products use ordinary rubber, which ages and hardens easily, resulting in poor sealing performance.

Thread Processing Precision

High-quality products feature clear, uniform threads without burrs or defects. When manually screwed in, the process should be smooth without jamming, and the fit should have moderate clearance. Inferior products have rough threads, are difficult to screw in, and can easily damage equipment threads.

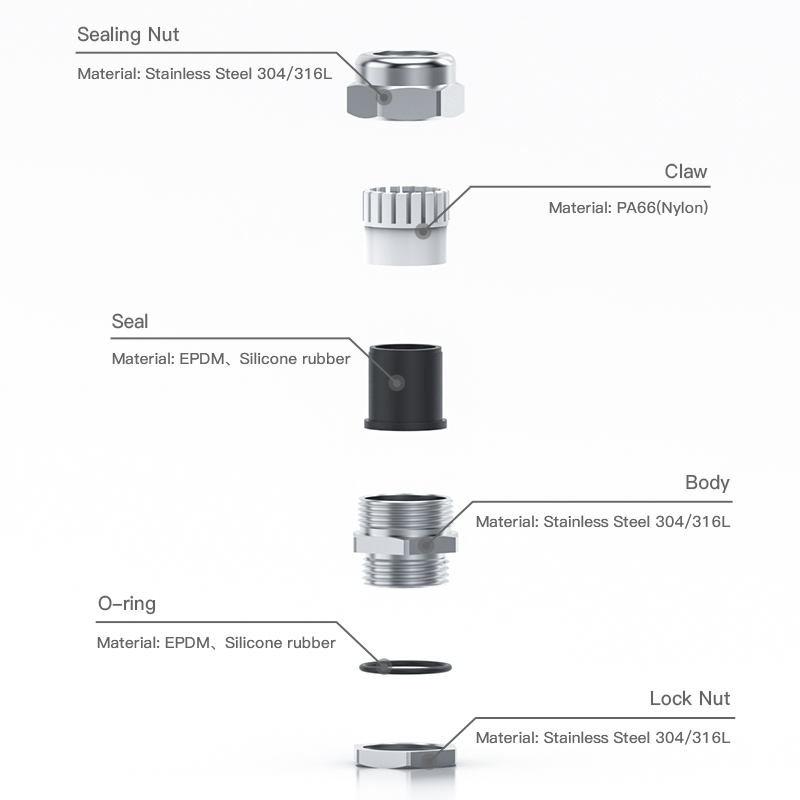

Clamping Component Design

The clamping jaws should be free of deformation and cracks, with flexible adjustment of the clamping range. High-quality products use nylon PA66 material with a flame retardancy rating of UL 94V-2, ensuring uniform and reliable clamping force.

IP68 Certification

Products with a genuine IP68 protection rating can be submerged in water over 1 meter deep for more than 30 minutes or withstand 10Bar water pressure without leakage. When purchasing, request third-party test reports from the supplier and do not rely solely on verbal promises.

Sealing Structure

High-quality products employ a triple-seal structure: interlocking clamping jaws and sealing components + O-ring + threaded compression nut. This design ensures good sealing even under harsh conditions like vibration and temperature changes.

International Certifications

High-quality products should carry international certifications such as UL, CE, ROHS, TUV, and ATEX. These marks should be clearly and properly displayed on the product or its packaging. It is advisable to choose brands certified under ISO9001 and IATF16949 quality management systems for more assured quality.

Explosion-Proof Certification

For hazardous locations, products certified under ATEX or IECEx standards are mandatory. The certification documents should be authentic and valid, verifiable on the certifying body's official website.

Standardized Packaging

High-quality products should come in neat, standardized packaging with clear and complete product information, including model/specification, material, protection rating, certification marks, production date, and batch number. The packaging should contain a user manual, certificate of conformity, and other relevant documents.

Brand Identification

Products from reputable brands should have clear brand logos and trademarks. The packaging should include the manufacturer's name, address, contact information, etc., for easy after-sales support.

Request Samples: Before bulk purchasing, ask the supplier for samples to conduct tests, including waterproofing, tensile strength, and high-temperature resistance tests.

Review Test Reports: Require suppliers to provide test reports from third-party laboratories to verify product performance parameters.

Conduct On-Site Visits: If possible, visit the manufacturer to observe production processes and quality control systems.

Compare Prices: Extremely low-priced products often cut corners. Opt for products with reasonable prices and good value for money.

Focus on After-Sales Service: Choose brands with comprehensive after-sales service systems and technical support.

Judging the quality of stainless steel cable glands requires comprehensive consideration from multiple dimensions: material, craftsmanship, protection level, certifications, and packaging. Choosing high-quality products is not only a commitment to equipment safety but also an investment in the long-term development of your enterprise. Zhejiang HONSUN Connector Co., Ltd., with its strict quality control and comprehensive product certifications, provides customers with reliable cable connection solutions.

Hot News

Hot News2026-03-02

2026-02-26

2026-02-05

2026-02-02

2026-01-28

2026-01-26

Copyright © Zhejiang Hongxiang Connector Co., Ltd. All Rights Reserved - Privacy Policy