Power cable glands – Tiny yet mighty protectors of electrical cables. They protect cables from dust, water and all of the things that cause damage. Power cable glands ensure that when cables enter machines or boxes, the connection is neat and no nasty substances are allowed in. If they do not have good cable glands, wires may become loose and broken, leading to machines that don’t work properly or accidents. We at HongXiang are keenly aware of the necessity for powerful performance with power cable glands. Our Special Function Cable Gland are constructed of the highest quality to ensure they last you for a very long time and keep your electrical systems safe and working well.

Decent power cable glands are hard to come by, because so many of them look the same but don’t work well. If you’re in need of cable glands that will last, then you want a material strong like metal, or at least sturdy plastic. At HongXiang, we take special care to make sure each EMC cable gland is crafted with tender love and care, and gone through the ringer in testing before it leaves our factory. Where you buy from Buying from the right place can save you money, as bad quality glands burst fast and have to be replaced often. We sell at wholesale prices, so you can purchase a lot of the cable glands for less. This is great for companies who require lots of these parts to keep their machines safe and running. And there are occasional issues with buying cheap glands, like leaks or loose wires. So, it is safer to believe in HongXiang where you always get high quality at good price. Our customers' feedbacks prove that our products are worthy because they are already being used in many projects and factories withstanding difficult conditions such as heavy rain, dust, hot weather.

Cable glands for mains wiring seem like a straightforward issue, but there are numerous potential complications that could arise if we don’t use them correctly (or install them properly). A bad fit is one problem, when the gland does not hold the cable tightly. This could allow water or dust to enter, which would later cause damage to the device's interior. You can fix this by measuring the cable and selecting a properly fitted gland. HongXiang offers glands in various sizes to avoid this problem. Another problem is using a wrong type of gland in a certain environment. For example, not all glands are made to be resistant against chemicals or bad weather. If you use the wrong gland, it may become damaged or wear out quickly. Our company installs different tests on one product to be sure that you have the perfect gland for your job. Sometimes, seals in the gland get old or crack. This allows moisture to enter, which can cause short circuits. This problem is solved by regular inspections of old glands and replacements from Wikimedia Commons64. At HongXiang, we also offer users precise instructions on how to install and maintain cable glands. This can facilitate people to use them correctly and not to make mistakes.

Power Cable Glands are critical components to assist and retain cable protection at the entry point of an electrical device or equipment. When properly installed, they protect cables from dust and water and damage, which extends the life of the cable and increases its reliability. Simple installation The following are relevant for the long life of power cable glands: For a long lasting life of power cable glands some simple attention should be taken into account during installation! In the first place, always select a power cable gland of with right size for the cable you are going to use. The cable gland connector also needs to be the right size, because if it is too large or small, it won’t grip the cable properly, and that can create problems such as water leaks or cable slip. HongXiang has a variety of sizes that fit different cables and you will find the right bulb. Then clean the cable and where you'll be mounting the gland before fitting. The gland can get gummed up with dirt or oil and not seal tight. Ensure that the cable is fed straight and does not become kinked or twisted while pulling through the gland. It helps the gland to clamp down on the cable uniformly, and without causing any harm. Once the cable is installed, tighten the gland carefully. Do not use force to remove it or you would break the gland or damage the cable.

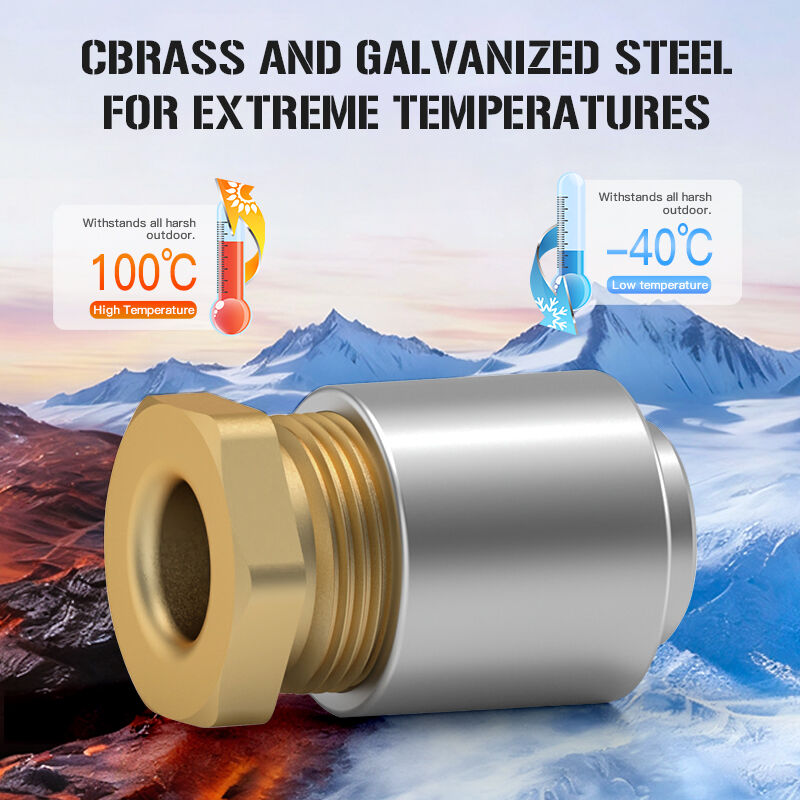

Hardware glands for power cables have been ameliorating and getting more ingenious with the aid of new technologies and designs. Hardware glands development has made them more user-friendly, longer-lasting, and able to protect cables even in more extreme environments. One of the biggest changes is better materials. HongXiang power cable glands nowadays are usually made of special kinds of plastics (like polycarbonate) or metals that can endure heat, chemicals, and weather much better than the materials used before. In other words, they can be utilized outside, in factories, and even underwater without getting broken or allowing water to enter

Power cable glands are also a step closer to being smart with the help of technology. Some of the glands have, in fact, been fitted with sensors or they have indicators that can alert you at an early stage that the gland is loose or that water has gotten in there. This is helpful in maintenance as workers can check the glands without taking them apart.

Since establishment, we have contributed to major national projects like China’s first aircraft carrier and built trusted partnerships with leading companies including Yutong Bus, Philips, ABB, and OPPLE, validating our reliability and product excellence.

We hold independent patents such as ZL201020530888.7 for advanced cable gland designs, supported by strong mold design and product innovation capabilities, allowing us to offer customized, high‑precision metal connectors for diverse industrial applications.

With a portfolio covering stainless steel, nylon, brass, and photovoltaic‑grade materials, we serve over 30 countries and provide end‑to‑end solutions—from R&D and manufacturing to installation and after‑sales—positioning us as a one‑stop global partner for cable connectivity needs.

All products comply with UL, CE, RoHS, TUV, ATEX, IP68, and other key international certifications, and are tested in accordance with German DIN, VDE, American UL, and European EN standards, ensuring safety, durability, and global market acceptance.

Copyright © Zhejiang Hongxiang Connector Co., Ltd. All Rights Reserved - Privacy Policy