In scenarios such as industrial automation, marine equipment, and rail transit, cable glands are like "invisible guards" — they may seem insignificant, but they silently shoulder the heavy responsibility of protecting cables, stabilizing signals, and resisting harsh environments. A poor-quality gland can, at best, cause equipment to "shut down" and signals to "drop out"; at worst, it may trigger safety accidents. A minor breakdown is manageable, but safety risks are catastrophic. Today, let's talk in detail about the HX.NP series cable gland from Hoonsun (Hongxiang Connector). This industrial-grade heavyweight that has passed CE and ROHS certifications — how exactly has it established a firm foothold in the industry and become a "solid benchmark" for reliable connections?

To talk about the HX.NP, we must first get to know its "maker" — Hoonsun (Yueqing Hongxiang Connector Manufacturing Co., Ltd.). As an established factory specializing in the R&D and production of cable glands and connectors, Hoonsun has been deeply rooted in the industry for many years. It has extremely "stringent" requirements for materials and craftsmanship, and better understands the practical needs of industrial sites that are exposed to "wind, sun, and bumps and bruises". Its products are sold well in the global industrial circle and are definitely "hot commodities" in areas such as automation equipment, distribution boxes, and construction machinery. Unlike some manufacturers that only follow the trend to produce homogenized products, Hoonsun focuses wholeheartedly on "durability and adaptability". The HX.NP series is its "proud work" of core technology, with its strength fully reflected in quality.

A useful cable gland must pass "four tests": corrosion resistance, water and dust proofing, vibration resistance, and easy installation. The HX.NP series is like an "all-rounder" — relying on precise material selection and thoughtful structural design, it firmly meets all these four requirements. Let's break it down step by step:

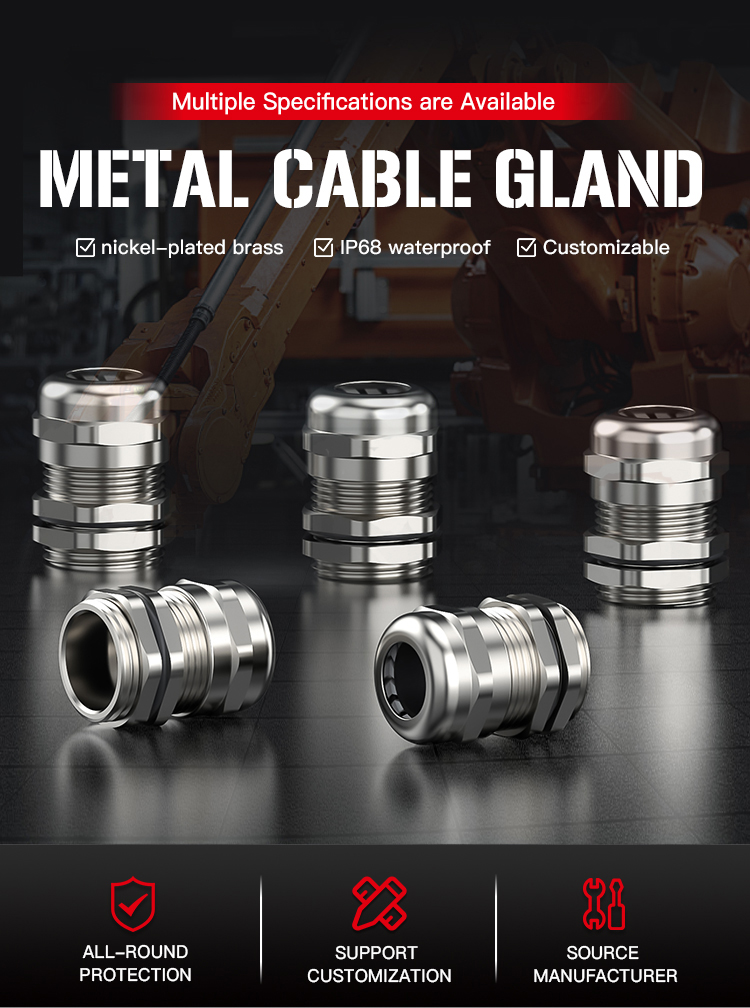

The industrial site is a "big examination room", where high temperature, high humidity, salt spray, dust, and chemical corrosion take turns to "make things difficult". Only with the right materials can the gland stand firm and last long. The HX.NP thoughtfully provides a "dual-material bonus" — optional nickel-plated brass and stainless steel. The main body is made of nickel-plated brass by default, which has high hardness and strong durability, and can easily resist salt spray corrosion. It can firmly hold its ground in "high-risk areas" such as marine and chemical industries with high humidity and salt content; if the environment is more harsh, you can directly choose 304/316L stainless steel, which takes corrosion resistance to a higher level and can be called a "corrosion killer".

In addition to the "tough" main body, the "sealing weak point" of the gland cannot be ignored. The seals and O-rings of the HX.NP are all made of EPDM material, and the claws are made of PA66 nylon. These materials have undergone high and low temperature "extreme tests". Even in freezing snow or intense sun exposure, they can maintain their elastic texture, and the sealing effect is not compromised at all — this is also its "unique skill" to achieve IP68 protection level. IP68 means complete dust isolation and can withstand long-term water immersion under 10bar pressure, just like putting a "waterproof and bulletproof vest" on the cable, full of a sense of security.

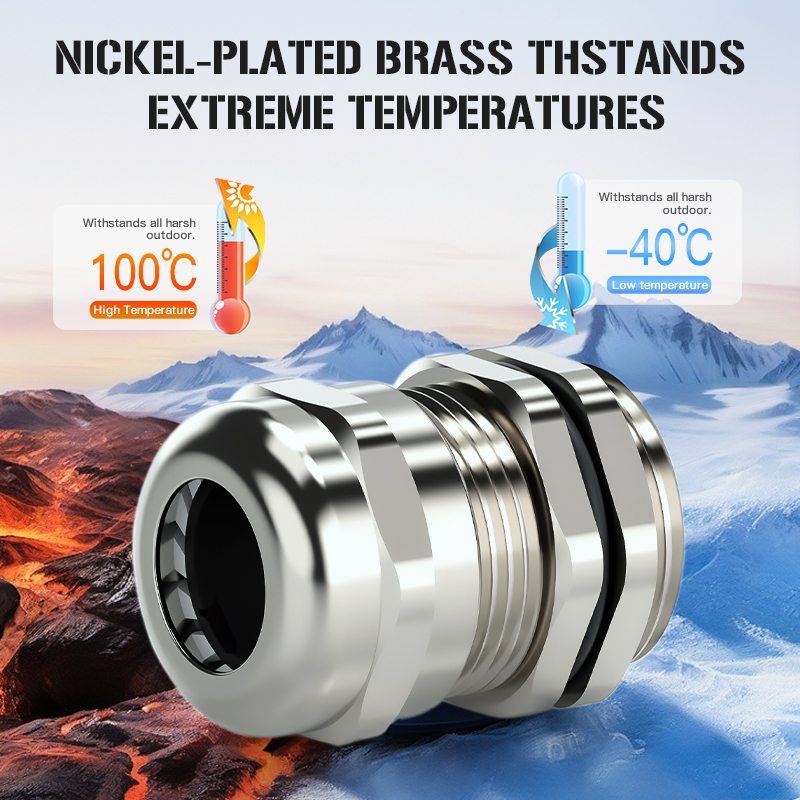

Whether it is outdoor equipment "frosted" in the cold winter in the north or automated production lines "burning hot" in high-temperature workshops, cable glands must withstand the test of temperature difference "roller coaster". The temperature resistance of the HX.NP can be called a "durability king": in static environments, it can withstand extreme temperature differences from -40℃ to 100℃, and even in the face of 120℃ high temperature for a short time, it can "remain motionless"; in dynamic scenarios with equipment operation vibration, it can also stably "stand guard" between -20℃ and 80℃, and withstand 100℃ high temperature for a short time without pressure.

Its strong "temperature resistance ability" relies entirely on the "golden combination" of material matching — EPDM seals do not crack at low temperatures or age at high temperatures, just like an "elastic expert"; the nickel-plated brass main body has uniform heat conduction, and will not deform due to "thermal expansion and contraction" caused by sudden temperature changes, fundamentally eliminating sealing "breakdowns" caused by temperature issues.

Vibration is inevitable when industrial equipment is running. Ordinary glands are like "untightened screws", which are easily loosened by vibration, thereby pulling the cable and causing signal "disconnection and shutdown". The HX.NP has long considered this point and comes with a "dual anti-loosening bonus" — thread locking structure + integrated lock nut design, just like "biting a tight knot" at the end of the hose. Its tensile and vibration resistance are directly maximized. Even in "high-frequency vibration fields" such as construction machinery and rail transit, it can firmly lock the cable, remaining motionless and not loose or falling off.

What's more thoughtful is that it is particularly "easy and labor-saving" to install — you can just twist the lock nut by hand, no need to carry heavy tools to toss. Even in "operation dead corners" such as pre-wiring or narrow spaces, it can be easily operated, greatly saving construction time. In addition, its thread precision is extremely high, which not only ensures "seamless" sealing but also achieves good grounding continuity, avoiding static electricity "accumulation and trouble", and guarding the safety bottom line in details.

Cables in different industrial scenarios have various thicknesses and thread standards. If the gland has poor compatibility, additional customization is required, which is both costly and takes up inventory — a real "trouble". The HX.NP can be called a "universal adaptation king" with surprisingly complete specifications: the cable diameter covers everything from 2mm thin cables to 84mm thick cables, with full coverage without dead ends; the thread diameter ranges from 12mm to 63mm, supporting all mainstream thread standards such as PG, NPT, and metric. Whether it is the "thin and small" cables of small automation equipment or the "thick and large" cables of large construction machinery, it can be accurately matched without additional customization, saving money and worry.

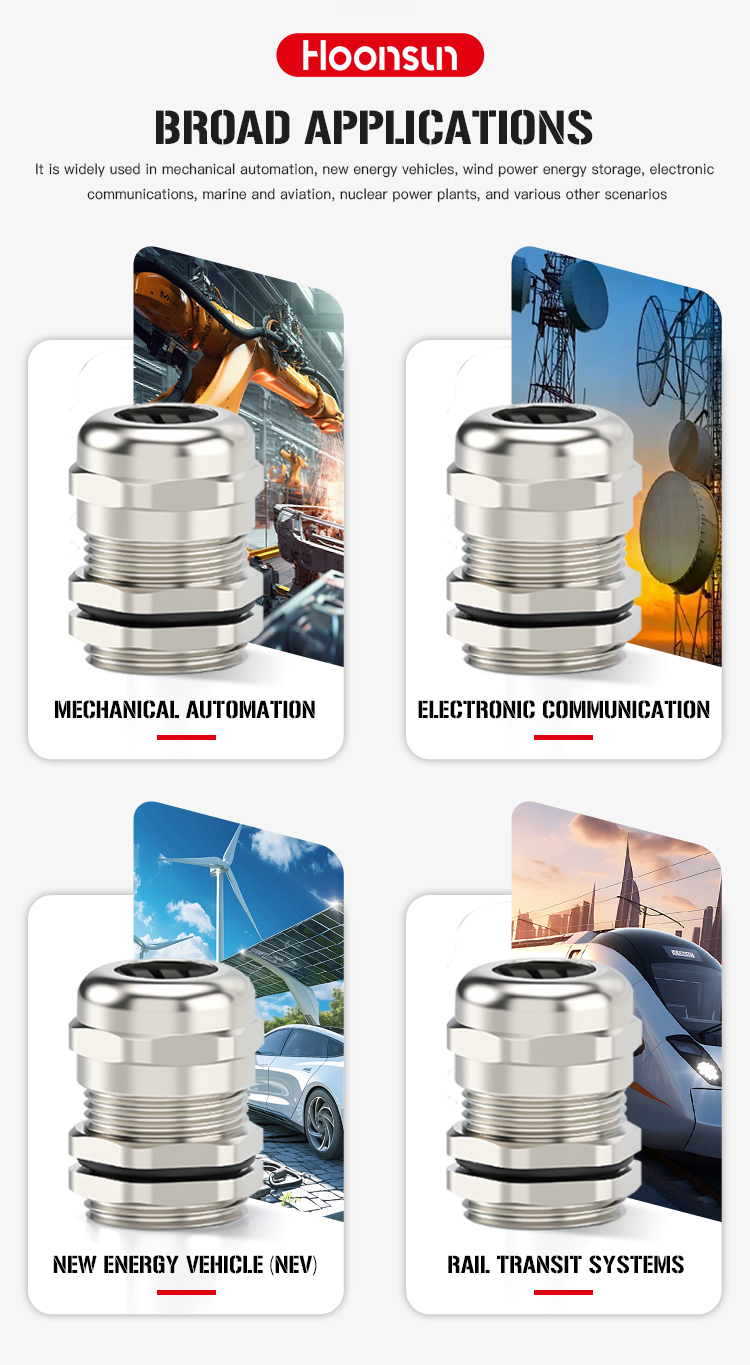

With these solid advantages, the "footprints" of the HX.NP are almost all over all core industrial fields. Especially in scenarios with "zero tolerance" for connection reliability, it is definitely a "must-have choice":

Industrial Automation Field: Automated production lines, robot equipment, PLC control cabinets. The workshop is full of floating dust and splashing oil, and the equipment vibrates constantly. The IP68 protection and vibration resistance design of the HX.NP is like installing a "protective shield" for the cable, adapting stably;

Marine Field: Marine decks, marine observation equipment. They are soaked in high-salt spray and high-humidity environments all year round, just like "taking a bath every day". The nickel-plated brass/stainless steel material of the HX.NP can effectively resist corrosion "erosion" and ensure long-term stable "operation" of the cable;

Rail Transit Field: Electrical systems of subways and high-speed rails. The temperature difference "fluctuates sharply" and vibration "never stops". The wide temperature adaptability and anti-loosening structure of the HX.NP can firmly stabilize the signal and prevent "disconnection failures";

Construction Machinery Field: Outdoor operation equipment such as excavators and cranes. They are exposed to wind, sun, and "heavy dust bombing". The IP68 protection and tensile design of the HX.NP can firmly protect the cable from damage and allow the equipment to "work" at ease.

In industrial production, reliable connection is the "lifeline" for stable equipment operation, and the cable gland is the "last post" on this lifeline. Its quality directly relates to the safety and stability of the entire system. The Hoonsun HX.NP series cable gland, with its solid high-quality materials, thoughtful structural design, full-scenario adaptability, and the "blessing" of international certifications such as CE and ROHS, not only stably solves the connection pain points in industrial sites but also perfectly interprets the industrial quality of "small parts with great responsibility" with strength.

If you are choosing a durable, reliable, and worry-free cable gland for your automation equipment or outdoor projects, don't hesitate — the Hoonsun HX.NP is definitely worth buying. In the industrial field, reliability is always the top priority. Choosing it means choosing peace of mind and reassurance!

Hot News

Hot News2026-03-02

2026-02-26

2026-02-05

2026-02-02

2026-01-28

2026-01-26

Copyright © Zhejiang Hongxiang Connector Co., Ltd. All Rights Reserved - Privacy Policy