Machines will work with proper sealing properly, if gland will not be sealed water tight leakage can occur and machines may stop functioning or get a short circuit. At our company HongXiang, we manufacture these parts with your tools and machines in mind. Water tight cable glands are available in different sizes and types as various machines require protection according to design. Learning about them is how you can choose the right one so that your gear is kept safe and in good working order.

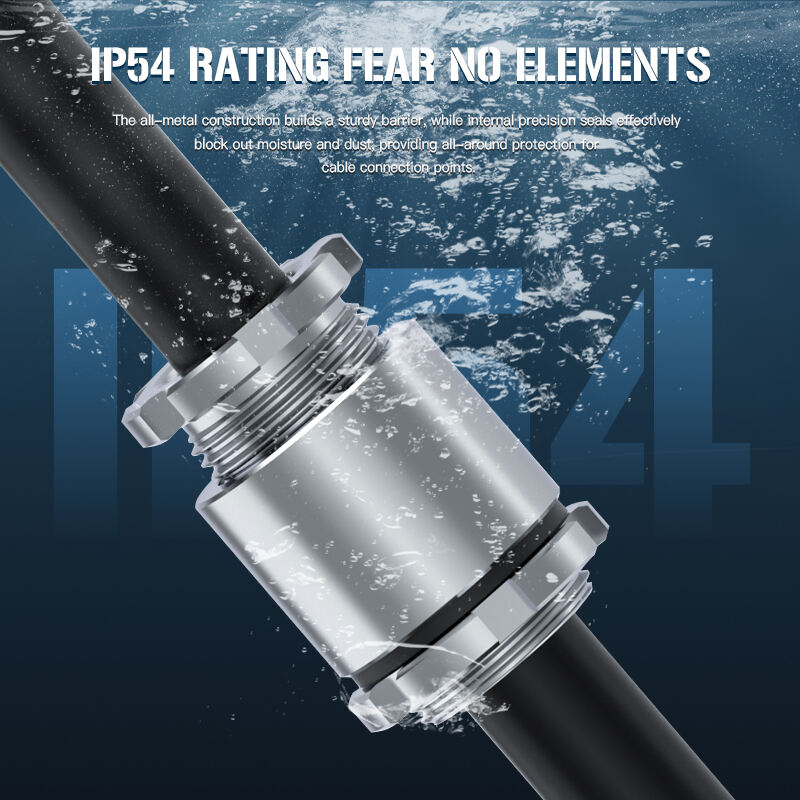

A world-class gland is made of resilient materials that can withstand punishing weather, heat or even chemicals. For instance HongXiang's waterproof gland are made to be durable these tough plastic or metal units will last and last. Also look to see if the glands have seals or rings inside — these help keep water out better.

It can be hard to come by a supplier that offers bulk purchasing services, and provides water tight glands in a good quality condition. People sometimes do find numerous options once they look online, but not every supplier is the same. You need someone who knows the technical requirements, not just a parts salesperson. HongXiang is one such industrial cable gland supplier.

Water tight glands are a type of special parts and it is used so that water does not get in machines or electric boxes. They are designed to keep water, dirt and dust from entering any opening where wire or cable enters or exits.

While water tight glands are designed to keep out water and dust, people will misuse them occasionally. This can create issues such as leakages or wire damage. One of the most common reasons is using a gland with an incorrect size for a cable.

With a portfolio covering stainless steel, nylon, brass, and photovoltaic‑grade materials, we serve over 30 countries and provide end‑to‑end solutions—from R&D and manufacturing to installation and after‑sales—positioning us as a one‑stop global partner for cable connectivity needs.

We hold independent patents such as ZL201020530888.7 for advanced cable gland designs, supported by strong mold design and product innovation capabilities, allowing us to offer customized, high‑precision metal connectors for diverse industrial applications.

All products comply with UL, CE, RoHS, TUV, ATEX, IP68, and other key international certifications, and are tested in accordance with German DIN, VDE, American UL, and European EN standards, ensuring safety, durability, and global market acceptance.

Since establishment, we have contributed to major national projects like China’s first aircraft carrier and built trusted partnerships with leading companies including Yutong Bus, Philips, ABB, and OPPLE, validating our reliability and product excellence.

Copyright © Zhejiang Hongxiang Connector Co., Ltd. All Rights Reserved - Privacy Policy